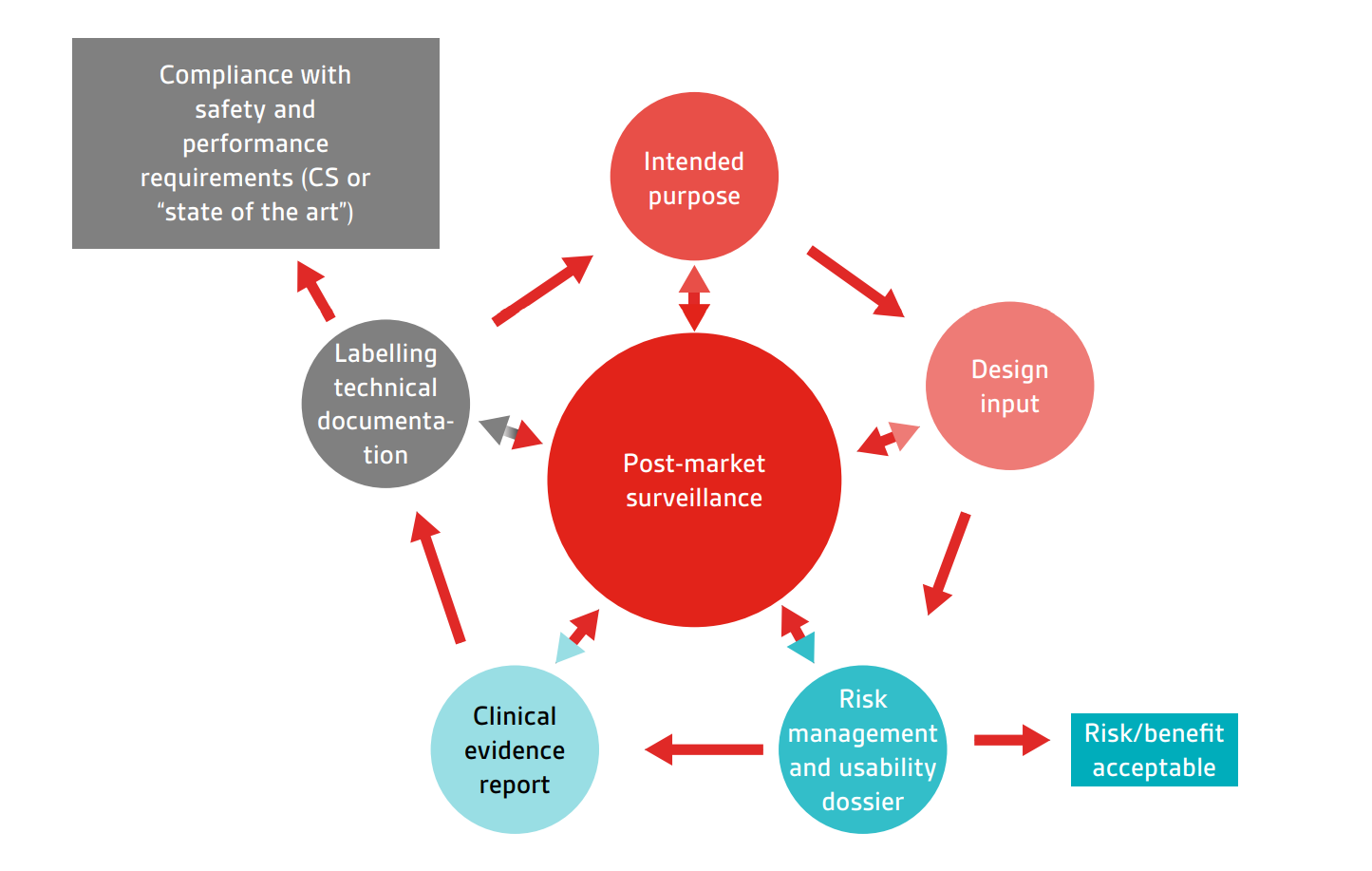

Performance evaluation and post-market surveillance Performance evaluation, in accordance with Article 56 and Annex XIII, including the new post-market performance follow-up (PMPF) plan must be defined within the QMS. This is another area that will have variation based on the classification of the device and should be adapted accordingly. The QMS process therefore needs to be sufficiently descriptive whileallowing the necessary variation to accommodate a manufacturer’s different types of devices. The PMPF will be a key element in the post-market surveillance activities. The plan may be a stand-alone document, or if it is sufficiently homogenous across a product family, can be part of the QMS as either a procedure or a template to be completed for each product. If it is intended to be a procedure, the scope of the procedure will need to be sufficiently clear to identify it as the plan. The introduction of the plan is one of the strong indications that the IVDR is shifting from reactive PMS (relying only on vigilance activities) to something more proactive. Post-market surveillance activities must be established, implemented and maintained in accordance with Article 78, and, as stated in the IVDR, this must be an integral part of the QMS (see Figure 3). Although the details of the post-market surveillance activities are not the subject of this paper, it is necessary to note that a number of links between this process and other areas of the QMS have been prescribed in the regulation, including risk management, performance evaluation, updates to the technical documentation, Corrective and Preventive Actions (CAPA), adverse event reporting and process/product monitoring. For IVDs in class C and D, the manufacturer shall prepare a Periodic Safety Update Report (PSUR). Ultimately, the manufacturer needs to demonstrate that the product is compliant with all safety and performance requirements, using as reference any Common Specifications (CS) that exist or ‘state-of-the-art’ comparisons.